SAFETY ALERT – SCAFFOLDING

Management of erected scaffolds, particularly modifications

- Only appropriately licensed scaffolders can erect, alter, repair, or dismantle scaffold, this should only occur with the approval of the principal contractor and scaffold contractor. The principal contractor must have site rules around the unauthorised modification of scaffold and have regular inspections to identify where unauthorised modifications occur.

- Scaffolders can assist with preventing unapproved modifications by documenting any work performed or completed by ways of daily handovers including photos and stage by stage handovers of works preformed.

Notify the principal contractor if unapproved modifications are performed.

Supervision/management of scaffolders and scaffolding work

Scaffolder contractors must:

- Plan work prior to start, have SWMS in place, ensure scaffold complies with legal requirements, trained and licensed workers. Principal contractors must:

- Obtain copies of design, engineers sign off, SWMS, scaffolders license, site preparation, induction for scaffolders, exclusion zones,

The principal contractor must halt the scaffolding work if they observe or are otherwise made aware of unsafe work practices.

Safe work method statements

Risk of falling higher than 2 m (HRWA) requires a SWMS. SWMS must have: Identification of work, hazards, controls measures (implemented, monitored, and reviewed)

SWMS Specific Hazards and control measures for:

- Falls when erecting/altering/dismantling, falling objects, inadequate training/licence, use of damage components, scaffold not compliant, unauthorised access to scaffold. SWMS must be site specific risk & controls like:

- Emergency contact details, site supervisor, atypical work methods.

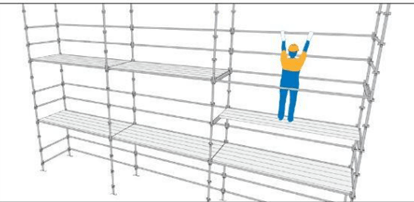

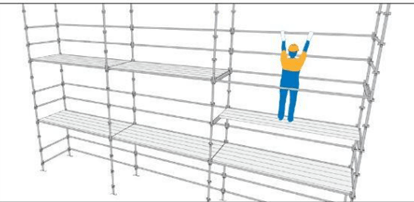

Safe method for erecting and dismantling scaffolds Work from behind edge protection at all times Work from below, using a temporary installation platform (min. 450mm wide) to install the edge protection and platforms for the next lift above (see Figure 5.1)

Harness-based systems must not be used as the primary control measure for risk of falls unless edge protection is not achievable Scaffold platforms must be fully planked at each lift and scaffolds will typically be dismantled using the reverse order of the erection method. Preferred method used is 1 meter lift sequence.

Handover certificates (written confirmation)

Handover certificate allows scaffold to be used and it comes from a licensed scaffolder who has inspected the scaffold, and state that construction of the scaffold is complete. It must be provided before first use of the scaffold after scaffolders have completed their scaffolding work (erected, altered or repaired). A copy of each handover certificate should be available on site for the duration of the project. Scaffolds are often erected in stages; thus, it may be impractical for a single handover certificate to apply to an entire scaffold.

Scaffolding tags can be a useful indicator at the entry point to the scaffold as to when the scaffold was last inspected.

Management of Erected Scaffolds

The principal contractor is primarily responsible for ensuring scaffolds are used correctly. This requires making sure all workers on site are aware of how the scaffold can be used and having means for identifying and rectifying issues (toolbox talks).

Preventing unauthorised access to scaffolds

The principal contractor is the person with management or control of the scaffold on site, and must not allow work (other than scaffolding work) to occur on a scaffold that does not have a valid handover certificate Scaffolding contractors must ensure their workers only access incomplete scaffolds if they hold the appropriate class of scaffold high risk work licence. While erecting or altering a scaffold, scaffolders should ensure other workers are not using or accessing the scaffold. Where incomplete scaffolds are to be left unattended (e.g. end of day), scaffolders should physically block off the access points and hang signage until construction is completed and a handover certificate provided.

Training and qualification of workers.

- Information, training, and supervision of workers interacting with scaffolds must be thorough, understandable, and monitored. Principal contractors should know a basic understanding of scaffold terminology and an understanding of duty ratings associated with scaffolding 1. 225kg (Light) 2. 450kg (Medium) 3. 675kg (Heavy)

- Scaffolders must be trained and competent to undertake their work, and should be capable of erecting/dismantling to a pre-determined design sequence, know what type of scaffolding work their HRWL allows them to complete have detailed knowledge of the scaffold systems they are using.

Only licensed scaffolders can undertake scaffolding work an unlicensed worker cannot alter, or modify scaffold in any way, this includes removing ties, planks hop ups, or any component on the scaffold, access the scaffold while it is incomplete, being modified or dismantled. This includes scaffolding labourers. There are two exceptions to this rule

- The worker is enrolled in an accredited HRWL scaffolding course with a registered training organisation and working under direct supervision from a person who holds the appropriate class of scaffolding HRWL, or

- The worker has obtained notice of satisfactory assessment from the registered training organisation within the last 60 days (but is yet to receive the HRWL.

Role of engineers, sign-offs and verifications

Simply holding an engineering degree or equivalent level of education does not make an engineer competent to undertake design analysis of scaffold structures. Engineers are relied on to assess the performance of a scaffold structure and determine its suitability for a particular application. This requires engineers to have a sound understanding of scaffolding load ratings, sequence of building, a sound understanding of scaffolding design standards